MANUFACTURING WORKSHOP PRACTICE 2 exposes the students to the fundamentals of manufacturing processes, the industrial environment, cultural issues, and hands-on experiences. This course enables students to apply knowledge and develop required technical skills in CNC machines, conventional machining, surface grinding machines, and TIG and MIG welding. The workshop practice helps the students practice appropriate safety procedures and standard operations for completing mini-projects and practical tasks. The practical skills also cover organizational and housekeeping activity, schedule maintenance, planning skills, supervising design, inspecting, and testing welding tasks in order to meet the quality requirements.

- Teacher: AINA AISHIKIN BINTI MOHAMAD ALI .

- Teacher: MOHD BUKHARI BIN MD JAHI BUKHARI

- Teacher: MUHAMMAD KHOIRUDIN BIN ZAKARIA khoirudin

- Teacher: LIZA ANNA BINTI MAT JUSOH MAT JUSOH

- Teacher: MOHD NAZROL BIN MD ALI MD ALI

- Teacher: SARIMAH BINTI ATAN sarimah

- Teacher: KHAIRUL FAIZAH BINTI SHAHRUDIN SHAHRUDIN

- Enrolled students: 42

- Teacher: AINA AISHIKIN BINTI MOHAMAD ALI .

- Teacher: LIZA ANNA BINTI MAT JUSOH MAT JUSOH

- Enrolled students: There are no students enrolled in this course.

JIG AND FIXTURE DESIGN covers basic production needs in industry. The topics taught includes types and functions of jigs and fixtures, supporting and locating, clamping and work holding principles, design economics, designing and construction plate jig and plate fixtures. This course also provides knowledge in management, sustainability and manufacturing systems.

- Teacher: MOHD IZWAN BIN SHAHARUDDIN BIN

- Enrolled students: 54

QUALITY CONTROL provides knowledge on basic principle and concept of quality including statistical method in controlling products quality or services. This course also emphasizes on the application of Control Chart and Quality Control tools and also explains the quality improvement technique.

- Teacher: HAZMAN BIN ABU HASSAN ABU HASSAN

- Teacher: EMADELLA BINTI RIFAI EMA

- Teacher: NOR`AIN BINTI SENIN SENIN

- Enrolled students: 46

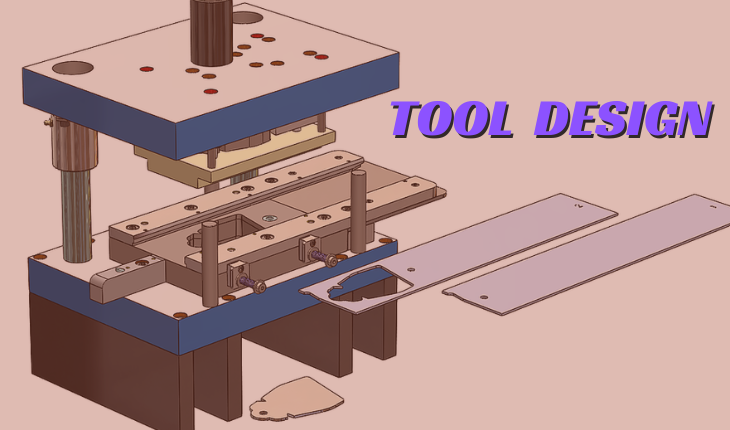

TOOL DESIGN exposes the students to the knowledge of datum concept, geometric tolerances and fundamentals to design tool based on clamping and locating principle. The topics also covers the principle of tool applications in metal and non-metal process. All the topics discussed will enable the students to plan and identify the use of tooling. They will also be exposed to the application of tooling in related industries.

- Teacher: MOHD NAZROL BIN MD ALI MD ALI

- Teacher: AZLAN SHAH B. KATIMAN Mr

- Enrolled students: 13

- Teacher: EMADELLA BINTI RIFAI EMA

- Enrolled students: There are no students enrolled in this course.